You see the effect of custom metal processing in Gold Coast every time you go into a car, pick up a phone, use a tool, or switch on an electrical gadget. Bolts and screws, flatware, pipe fittings, vehicle parts, and even screwdrivers are examples of manufactured metal products in Gold Coast. However, many of us struggle to comprehend precise metal fabrication in Gold Coast, let alone how it influences every aspect of our lives. Metal fabrication involves molding metal things through bending or cutting to create products.

The History of Metal Fabrication

According to the copper pendant archaeologists found in 9,000 BCE in northern Iraq, humans have been machining and mining metal for the previous 10 millennia. Fabrication shops that we see today began to exist during the Industrial Revolution when there was a high demand for sheet metal. With the invention of the hydraulic press, manufacturers started applying unprecedented pressures to metal pieces which in turn transformed the industry of metal fabrication.

On a broad scale, metal fabrication became a necessity to form systems of telegraph lines, railroads, weapons, printing presses, tools, etc. All these systems used to rely on machine shops for cutting, joining, bending, and forming like today. Later, the introduction of compressed air turned riveting into an importance part of fabrication, more efficient and much easier.

At the beginning of the 20th century, the industry of metal fabrication was considered to have an important role in our lives. Today, machining is performed on a vast scale, ranging from large manufacturing plants with thousands of employees to small, family-run operations.

Metal Fabrication Technology is a type of technology used to make metal objects

Metal fabrication is a relatively older process that was prevalent since its inception in the 1400s. As the industrial revolution gained precedence, so did the process and with the rise in modern technology, metal fabrication grew to advanced proportions. Even though the basic principles remain somewhat constant, the technological advancements paved the way for newer designs in the field of automation, transport, construction and the likes. Suffice to say, with the growing demand for metallic products, metal fabrication isn’t something that’s going to go away anytime soon. Metal fabrication plays a crucial role in producing a wide range of products, including but not limited to foundation anchor bolts used in construction projects. The entire process of fabrication of metals follows three main elements which make up the core of the manufacturing process:

1. CAD software

Computer-aided design, or CAD for short, is crucial in developing metal fabrication in Gold Coast. Designs are made using the software which is later used to create the final product during the fabrication process. Thanks to the versatility of the software, 3D models can be made seamlessly and with less effort and implemented into manufacturing without any delay. With an array of programming languages ready to be used, users can program the application to create models they see fit. It might be worth noting that programming is the cornerstone for all the automated fabrication processes that make use of CAD for designing purposes. As a result, products can be made easily with less human intervention.

Machinery: With more advanced machines in tow, the time taken to produce new products is less and at the same time, the efficiency of other processes such as cutting also improves. These technologies are projected to grow in popularity in the coming years, particularly as fabricators want more flexibility from their machinery.

2. Automation

In recent years, fabrication machinery comes equipped with programming capabilities to allow the automated completion of projects, which requires minimum human involvement. As a result, manufacturers experience improved precision and reproducibility. Moreover, various automated tools are available for several processes, such as welding, cutting, folding, and more.

3. Machinery

With more advanced machines in tow, the time taken to produce new products is less and at the same time, the efficiency of other processes such as cutting also improves. These technologies are projected to grow in popularity in the coming years, particularly as fabricators want more flexibility from their machinery.

Metal Fabrication Processes Types

Metal manufacturing involves several different processes. The shape of the part, the sort of use it will receive, and the material it is built of will influence the precise mix of metal or steel manufacturing procedures used. Here are some examples of options for various fabrication processes:

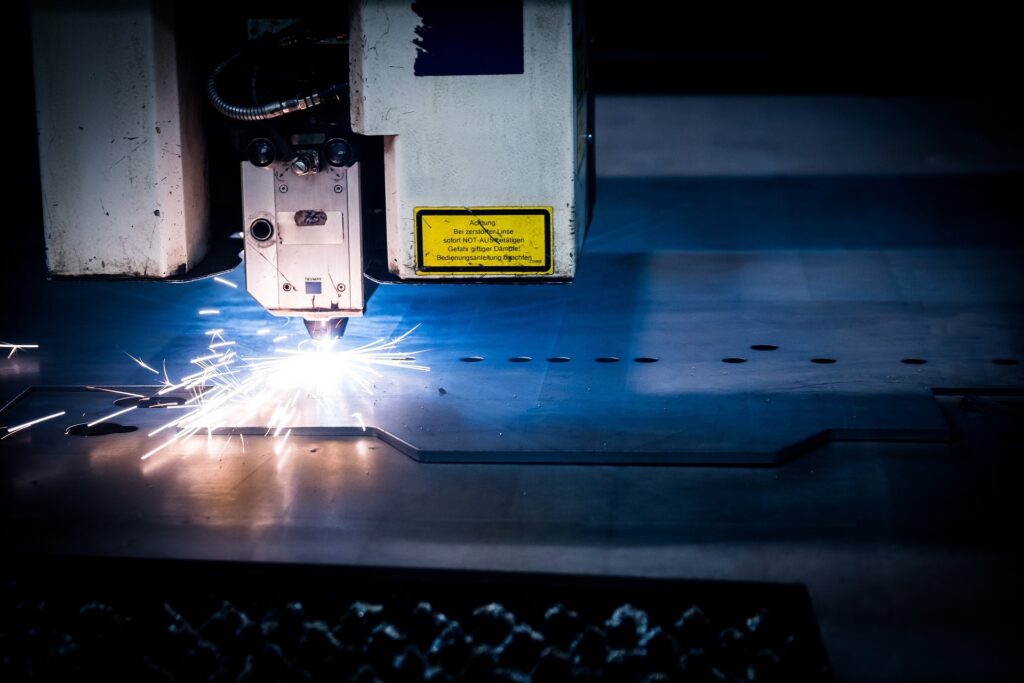

Cutting: The most basic operation in metal manufacturing is cutting, which can be achieved using lasers, waterjets, shearing, sawing, or flame cutting. This is how the sheet metal is transformed into a component of the desired size and shape. Waterjet or laser cutting is the most common technology used today.

Casting: A die creates a mold, which the fabricator then fills with molten metal. After removing the dice, the metal cools and solidifies, and the portion remains.

Forging: High-pressure equipment compresses raw metal so that it can be bent and shaped by a fabricator.

Turrets pound pre-designed patterns into metal, either for ornamental or functional purposes.

Drawing: A tensile force pulls molten material into a tapering die.

Milling: A cutting mechanism creates perforations in metal, which can be non-circular due to the machine’s design.

Drilling: A drill uses a circular bit to create holes in metal.

Turning: A technician places the chunk of metal on a rotating platform and uses a tool to cut it axially while it spins.

Mechanism of Custom Metal Fabrication

Typically, metal fabrication begins with an idea that involves metal customization for a particular task. For instance, when a tech company is looking for a machined aluminum cover for their latest gadget. Firstly, the company will start working on the design and send it to several machine shops for price quotation. The shops will analyze the design, calculate the production cost and reply to the company with the cost and estimated deadline.

Once the deal is finalized with a suitable machine shop, the process of custom metal fabrication starts. It consists of the following steps:

Design

In this phase, the design is analyzed and adjusted as per the requirements of the customers. As soon as the pattern is finalized, manufacturers use CAD software to produce the design.

Prototyping

This step is the most common one, though it is not a requirement for every project. A rapid prototype is produced in this phase using rapid sheet metal or 3D prototyping. Then the prototype is analyzed by the design team and customer for any adjustments.

Programming

At this stage, the CAD design of the product is translated into the programming of computer-controlled machines that would be required for automated punching, cutting, and turning.

Fabrication

After the completion of programming, the process of fabrication begins. Time consumption during the process mainly depends on the complexity of the processes used and the demand of the machine shop. This step further involves several steps, such as punching, cutting, machining, folding, welding, etc.

Finishing

This phase includes refining edges and surfaces or applying different types of coating options, like powder coating.

Assembly

Although finishing is generally the last step, some fabrication services also provide assembly consisting of welding or electrical integrations.

Summary

Metal fabrication is a process of molding, cutting, bending, or turning metal pieces into a desired structure. This process plays a vital role in creating structures and products for businesses. Fortunately, there are a lot of metal fabrication services to choose from these days, but it is important to rely only on experienced and skilled companies for the procedure.